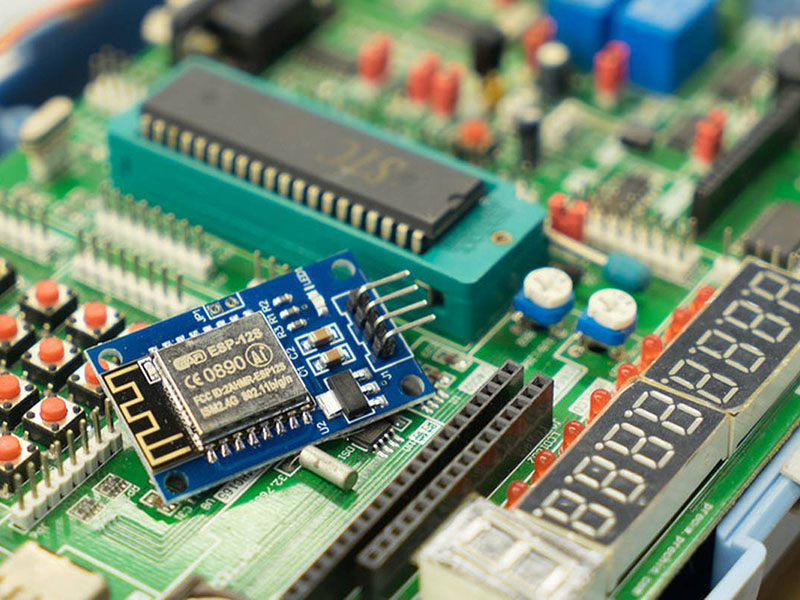

PCB assembly manufacturing is the process of producing printed circuit board (PCB) assemblies, which are used to connect electronic components in a wide variety of electronic devices. PCBs are used in everything from computers and cell phones to appliances and automotive systems.

Overview of the PCB Assembly Process

The PCB assembly process involves several steps, including:

- Design: The first step in the PCB assembly process is to design the circuit board. This involves creating a layout of the PCB, including the placement of components and the routing of traces (conductive pathways) between them. The design is usually created using computer-aided design (CAD) software.

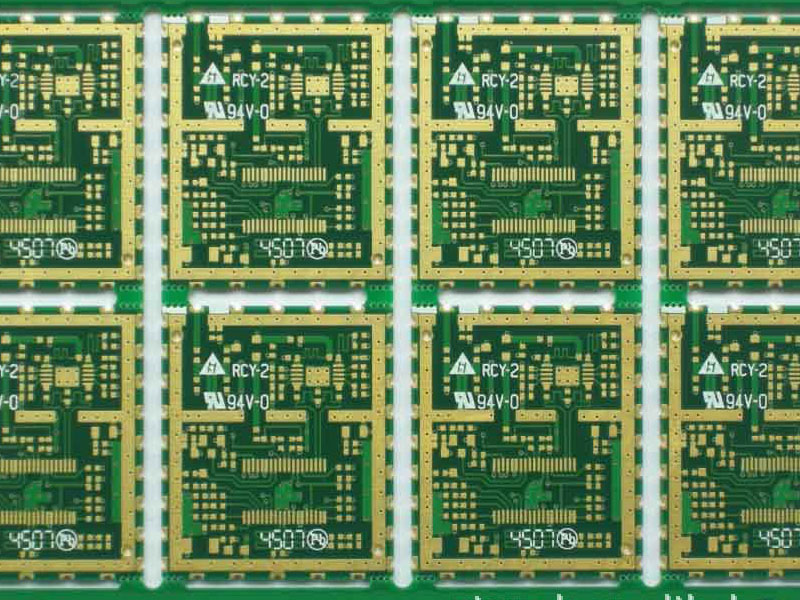

- Fabrication: Once the design is complete, the PCB is fabricated using a process called photolithography. This involves creating a negative image of the PCB layout on a photosensitive film, which is then used to etch the circuit pattern onto a copper-clad PCB substrate.

- Soldering: After the PCB has been fabricated, components are attached to it using a soldering process. This typically involves placing the components on the PCB and then heating them to a temperature high enough to melt the solder, which bonds the components to the PCB.

- Testing: After the PCB has been assembled, it is tested to ensure that it is functioning properly. This may involve testing the electrical connections between components, as well as the overall functionality of the circuit.

PCB Assembly Manufacturing for Telecommunications

PCB assembly manufacturing plays a critical role in the production of telecommunications devices, such as phones, tablets, and networking equipment. These devices rely on PCBs to connect the various electronic components that make up the device, such as processors, memory, and input/output interfaces.

Examples of Telecommunications Devices that Use PCB Assembly Manufacturing

Some examples of telecommunications devices that use PCB assembly manufacturing include:

- Cell phones: Modern cell phones are complex electronic devices that contain a wide variety of components, including processors, memory, displays, cameras, and wireless communication hardware. All of these components are connected using PCBs.

- Tablets: Like cell phones, tablets are electronic devices that contain a variety of components, including processors, memory, displays, and wireless communication hardware. PCBs are used to connect these components and enable the device to function.

- Networking equipment: Networking equipment, such as routers, switches, and access points, also use PCBs to connect the various components that make up the device.

The Role of PCB Assembly Manufacturing in the Design and Functionality of Telecommunications Devices

PCB assembly manufacturing plays a vital role in the design and functionality of telecommunications devices. The layout of the PCB and the placement of components on it can have a significant impact on the device’s performance, including factors such as signal strength, power consumption, and overall reliability.

Differences Between PCB Assembly Manufacturing for Telecommunications and Other Industries

While the basic principles of PCB assembly manufacturing are the same across all industries, there are some differences in the way that PCBs are used and produced in the telecommunications industry.

Materials and Components Used in PCB Assembly Manufacturing for Telecommunications

One key difference between PCB assembly manufacturing for telecommunications and other industries is the materials and components that are used. Telecommunications devices often require PCBs with specialized properties, such as the ability to transmit high-frequency signals with minimal loss or to operate in harsh environments. As a result, the materials and components used in PCB assembly manufacturing for telecommunications may be different from those used in other industries

Quality Control and Testing in PCB Assembly Manufacturing for Telecommunications

The telecommunications industry has strict quality control and testing standards for PCB assembly manufacturing due to the critical nature of the devices that use these PCBs. In addition to testing the functionality of the PCB itself, telecommunications devices often undergo extensive testing to ensure that they meet regulatory standards and are able to withstand the demands of their intended environment.

Conclusion

PCB assembly manufacturing plays a crucial role in the production of telecommunications devices, from cell phones and tablets to networking equipment. The materials, components, and design considerations for PCBs used in telecommunications are often different from those used in other industries due to the specialized requirements of these devices. Quality control and testing are also of paramount importance in the telecommunications industry to ensure the reliability and performance of the devices that use PCBs.

Looking to the future, we can expect to see ongoing developments in PCB assembly manufacturing for telecommunications, as the industry continues to push the boundaries of what is possible with these vital components.