RF (Radio Frequency) PCB layout and routing are critical aspects of mobile phone design. Careful consideration and proper implementation of these techniques are essential to ensure optimal performance and reduce interference. In this post, we will discuss several key factors to prioritize when designing mobile phone PCBs.

Power and Ground Plane Handling:

Even with a well-designed PCB layout, inadequate handling of power and ground planes can lead to interference and decreased product performance. Therefore, minimizing noise interference between power and ground lines is crucial. Here are some strategies to achieve this:

1) Add decoupling capacitors between power and ground lines.

2) Widen power and ground traces, with ground traces generally wider than power traces. The relationship between trace widths can be Ground trace > Power trace > Signal trace. Typical signal trace width is around 0.2 – 0.3mm, and the minimum trace width can be as small as 0.05 – 0.07mm, while power traces are between 1.2 – 2.5mm wide. For PCBs with digital circuits, a wide ground trace can form a loop to create a ground plane (this may not be suitable for analog circuits).

3) Utilize large copper areas for the ground plane. Unused areas on the PCB can also be connected to the ground plane. Alternatively, consider using multilayer boards where power and ground planes occupy separate layers.

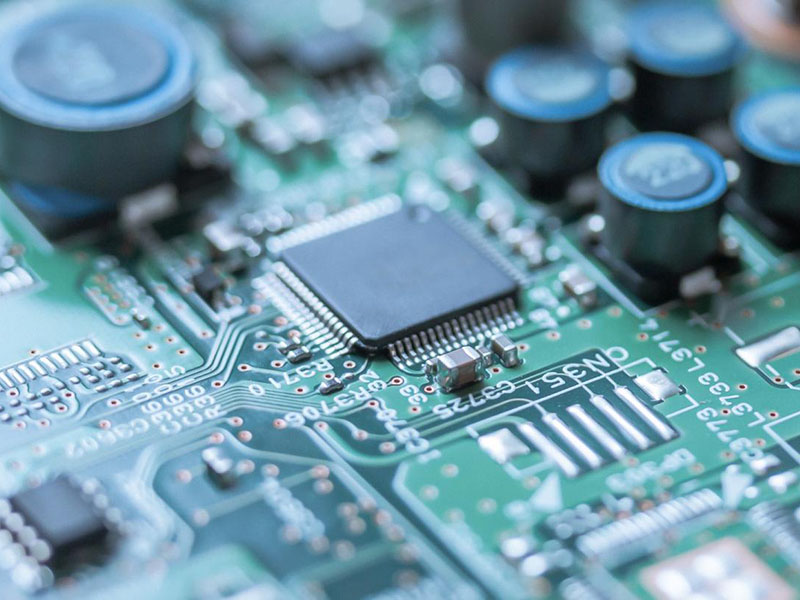

Shared Ground Handling for Digital and Analog Circuits:

Modern PCBs often consist of a mix of digital and analog circuits. Therefore, designers must address the issue of mutual interference, especially concerning noise on the ground plane. High-frequency signals from digital circuits and the sensitivity of analog circuits demand careful consideration. To mitigate this, follow these guidelines:

1) Keep high-frequency signal traces from sensitive analog components as far away as possible.

2) Internally separate digital and analog ground planes. They should not be connected within the PCB except at specific interface points with the external world (e.g., connectors). There should be only one connection point between the digital and analog ground planes. However, there are cases where separate ground planes are necessary based on system design.

Signal Routing on Power (or Ground) Layers:

When dealing with multilayer PCBs, it is common to have some unused traces after routing on signal layers. To avoid waste and minimize production costs, consider routing on power (or ground) layers. Start by utilizing the power layer and then the ground layer, as maintaining the integrity of the ground plane is essential.

Handling Component Connections in Large Copper Areas:

In large ground or power areas, components often have their legs connected to them. It is essential to consider these connections carefully to balance electrical performance and assembly requirements. Connecting component legs directly to the copper area is good for electrical performance but may have drawbacks during assembly, such as:

1) The need for high-power heating during soldering.

2) Increased likelihood of solder joint defects.

To address these issues, consider using thermal relief pads or heat shields (also known as thermal pads). These features help dissipate heat more evenly during soldering and reduce the risk of solder joint defects. Similar considerations apply to legs connected to power or ground layers in multilayer PCBs.

Role of Network Systems in Routing:

Many CAD systems use network systems to determine routing paths. A dense network may increase routing possibilities but can result in larger data files and potentially slow down the device’s operation. Conversely, a sparse network can limit routing options and impact signal integrity. Therefore, a balanced network system that supports efficient routing is crucial. Standard component leg spacing is 0.1 inches (2.54mm), so the network system’s base is often set at 0.1 inches or smaller multiples, such as 0.05 inches, 0.025 inches, or 0.02 inches.

Conclusion:

Proper RF PCB layout and routing are vital for the optimal performance of mobile phones. By focusing on power and ground plane handling, shared ground management for digital and analog circuits, signal routing on power (or ground) layers, component connections in large copper areas, and the role of network systems in routing, designers can achieve high-quality, low-interference PCBs, leading to superior mobile phone performance.