As a high-tech product, LED display screens have played an indispensable role in conveying essential information and providing unparalleled visual experiences in people’s daily lives after more than two decades of market development. Controlled by computers, these intelligent full-color LED display screens integrate light and electricity, widely applied in various fields. They utilize LED pixels arranged in an array to form screens that showcase different images based on varied LED driving methods. The quality of LED display screens heavily relies on the specialized driver ICs.

Basic Concept of Driver ICs

a. Introduction to Display Driver ICs

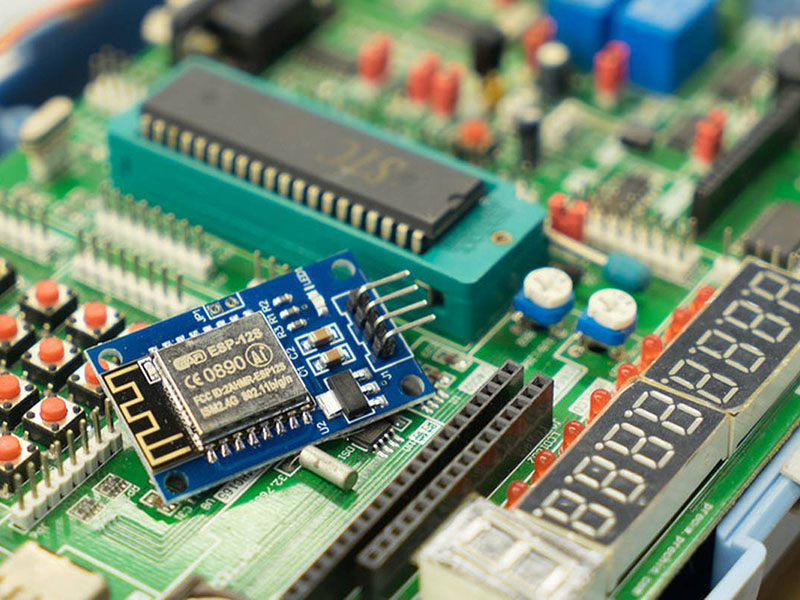

LED display screen specialized driver chips are specifically designed for driving LED display screens based on LED luminous characteristics. These driver ICs significantly impact the grayscale and refresh rate of LED screens. The maturity of LED display screen driver IC technology has propelled a qualitative leap in display quality. With features like high output current and constant current, these driver ICs enable LED screens to be used in high-current, high-resolution scenarios, driving the diversity of displayed content and application fields.

LED driver chips can be divided into general-purpose and specialized types. General-purpose chips, like the 74HC595, are not specifically designed for LEDs but serve logic functions for LED screens, typically used in lower-end products like indoor single or dual-color screens. Specialized chips are tailored for LED screens, providing constant current sources crucial for stable LED driving, eliminating flickering, and ensuring high-quality visuals. Top Used LED display provider like IAMLEDWALL used some specialized chips incorporate additional functions tailored to different industry requirements, such as LED error detection, current gain control, and current correction.

Performance Metrics of Driver ICs

In LED display screens, refresh rate, grayscale levels, and image representation are vital metrics, demanding high consistency in channel currents, fast communication interface rates, and constant current response from LED driver ICs. Traditionally, there’s been a trade-off between refresh rate, grayscale, and utilization – ensuring one or two metrics are excellent often sacrifices the others. However, advancements in technology from driver IC manufacturers have mitigated these issues.

In addition to these, in applications of LED full-color display screens, maintaining low brightness with high grayscale becomes a critical standard, testing the performance of driver ICs.

Role, Working Principle, and Driving Modes of LED Driver ICs

The primary role of LED driver ICs involves receiving display data following specified protocols (from receiving cards or video processors) and internally generating PWM and current variations, outputting PWM currents related to brightness and grayscale to illuminate LEDs. These driver ICs, together with logic ICs and MOS switches, collectively influence the display functions and the resultant visual effects of LED screens.

The driver chip contains a constant current generation circuit, allowing the setting of output constant current values via external resistor configuration. Through the chip’s enable terminal, control over the switch time of output channels is achieved, with a switching frequency of up to one megahertz (1MHz). The rapid response of current output supports applications with high-color gradation changes and high screen refresh rates. Built-in open-circuit detection, overheat shutdown, and overcurrent protection greatly enhance the reliability of application systems.

Driver ICs are mainly categorized into constant current and voltage stabilizing driving modes.

Constant current driving maintains a consistent output current, while the output DC voltage varies within a certain range depending on the load resistance; however, it’s essential to avoid complete load open circuits, and these circuits can be relatively expensive. The maximum permissible current and voltage values used restrict the number of LEDs that can be employed.

Voltage stabilizing driving maintains a fixed output voltage, while the output current fluctuates with changes in the load; these circuits can withstand load open circuits but strictly prohibit complete load short circuits. To drive LEDs using voltage stabilizing circuits, suitable resistors need to be added to ensure uniform brightness across LED strings, which can be influenced by voltage fluctuations from rectification.

The development and overview of LED display driver ICs in China

1. Evolution of LED Display Driver ICs

In the 1990s, LED display screens primarily used single or dual-color displays with constant voltage driver ICs. In 1997, China introduced the specialized LED display driver control chip 9701, which leaped from 16-level grayscale to 8192-level grayscale, enabling real-time video rendering. Subsequently, due to the light-emitting characteristics of LEDs, constant current driving became the choice for full-color LED displays. Higher integration of 16-channel drivers replaced 8-channel ones. Towards the late ’90s, companies like Toshiba (Japan), Allegro, and TI (USA) introduced 16-channel LED constant current driver chips. In the early 21st century, Taiwanese companies also started mass-producing and using these driver chips. Additionally, some IC manufacturers introduced highly integrated 48-channel LED constant current driver chips to solve PCB wiring issues for small-pitch LED displays.

2. Current Status of Driver IC Market

Since Q4 2020, due to robust market demand and increased raw material costs, display driver IC manufacturers have raised product prices by approximately 10% to 20%. Amid rising costs, they initiated another round of price hikes from April, reaching up to 15% to 20%. The shortage of display driver ICs began around Q3 2020, with supply initially meeting only 50% of market demand, causing distress for small and medium enterprises. This scarcity eased towards the end of 2021.

Under the “chip shortage” wave starting in 2021, some display IC prices surged by 30%, even reaching a situation of demand without a price tag. This shortage significantly affected the LED display industry, given China’s relatively high dependence on high-end chip imports. The global shipment of driver chips is expected to reach 122.14 billion units in 2023, with an estimated 45.651 billion units in the Chinese market.

In 2021, the total sales of domestic display driver ICs reached around 5 billion RMB, primarily benefiting from a surge in demand in the second quarter of the previous year, causing price spikes. This surge, initially perceived as monopolistic behavior by industry professionals, led to related disputes.

3. Development of Mini/Micro LED Technology and its Challenge to Traditional Driver ICs

The specialized LED display driver ICs sell approximately 1 billion units per month in China. With the rapid development of Mini/Micro LED technology and accelerated application market demand, the requirement is expected to exceed 2 billion units per month by 2024.

Technological advancements drive high-quality innovation in the display industry. The LED display driver IC, functioning as the central nervous system similar to the human brain, governs the visual effects of the entire display. In applications like small-pitch LED displays, maintaining comfortable viewing for prolonged periods requires stringent standards such as low brightness and high grayscale in driver IC performance.

4. Future Technological Development Directions for Driver ICs

Existing product technologies will continue optimizing to resolve issues like trailing shadows, “jitter,” grayscale, low brightness with high grayscale, enhancing refresh rates, picture quality, interference resistance, reducing power consumption, and smart energy efficiency. Due to current IC sizes not meeting demands for Mini/Micro LED ultra-fine pitch and ultra-dense chip products, related IC products will evolve towards higher integration.

Efficiency remains a perpetual pursuit in LED displays as green energy sources, driving the evaluation of driver IC performance. Efforts focus on effectively reducing constant current inflection voltage, decreasing operational voltage, and current while optimizing IC algorithms and designs. Some manufacturers have introduced constant current driver ICs with a low transition voltage of 0.2V, improving LED utilization by over 15% compared to conventional products, leading to a 16% reduction in power consumption.

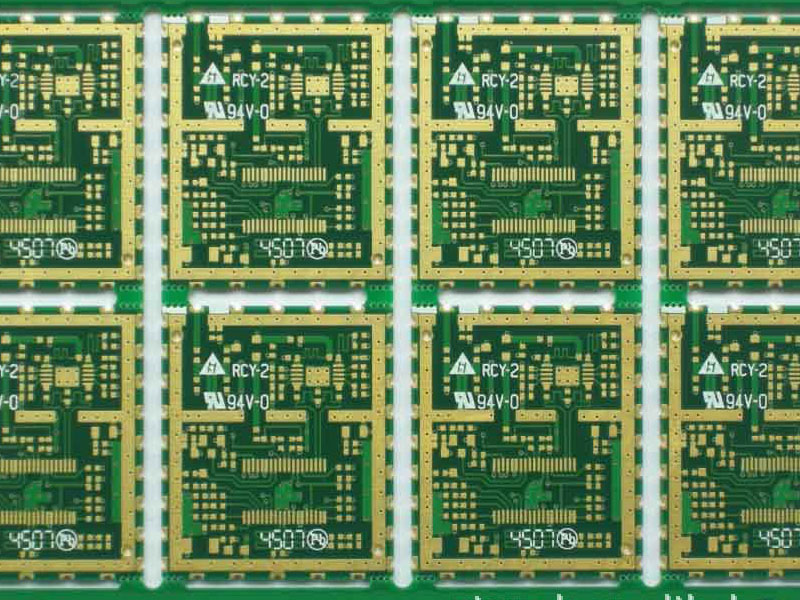

As pixel pitch rapidly decreases in LED displays, the number of components per unit area significantly increases. For instance, a P1.9 small-pitch LED requires 180 constant current driver ICs, 45 row drivers, and 2 138 drivers for a 15-scan 160*90 module. This density challenges PCB wiring space and circuit design while impacting module reliability. The demand for fewer driver ICs and more PCB wiring area compels driver ICs towards highly integrated technological pathways.

Industry Outlook for Display Driver ICs

Impact of Pandemic on IC Production Capacity: The pandemic affected new expansions and production lines of IC companies in regions like Shanghai, Suzhou, and Wuxi, slowing down new capacity releases. However, increased demand for LED displays in Q2 2021, followed by a slowdown due to the pandemic in early 2022, added to inventory pressures. The industry, including driver ICs, might experience relief from supply-demand tension.

New Requirements in the Era of Ultra-Fine Pitch Displays: As Mini/Micro LED applications accelerate in the consumer electronics industry, more IC companies might enter the LED display domain, potentially alleviating supply-demand pressures.

In light of these trends, the LED display industry increasingly demands driver IC performance optimization. Meeting these demands entails focusing on multiple requirements like low power consumption, low grayscale with high refresh rates, grayscale correction, high integration, high frame rates, PWM+AM, etc.

Design-wise, meeting low-power circuit design necessitates optimizing internal circuit power consumption, achieving over 48 channels for high integration, and adopting 128-scan high scan designs. Control modules should operate at low power, reducing power consumption from 12.5 (W/㎡) to 2 (W/㎡). Technological advancements from 180nm to 40nm are essential to meet these requirements.

With applications in various sectors escalating, meeting new market demands through technological advancements remains a key task for the industry to prepare for future market needs.

Conclusion

LED display driver ICs play a crucial role in driving the development of LED displays. The constantly evolving landscape of LED display applications poses challenges for driver ICs, necessitating substantial breakthroughs in technology to aid the industry’s growth. Future advancements will likely reveal the true potential of LED displays, inspiring further innovation in driver ICs.