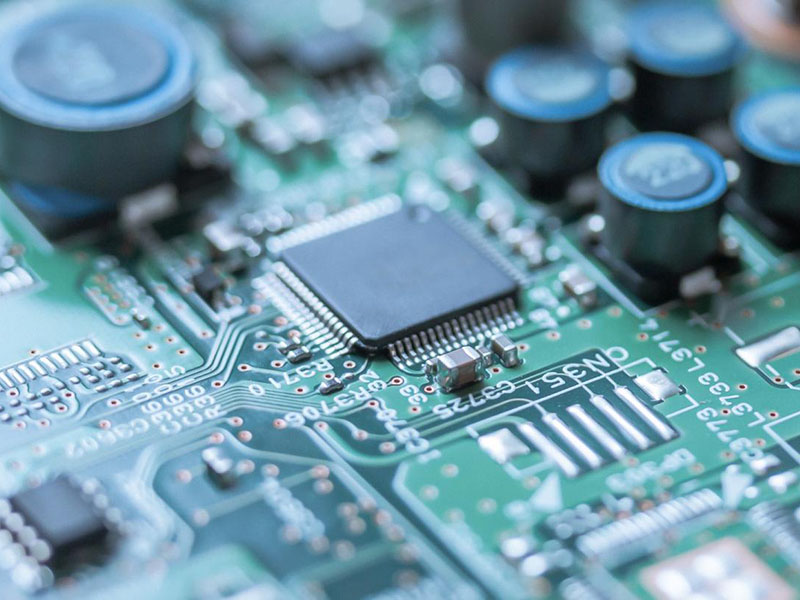

When designing solar-powered embedded systems for outdoor applications, it is crucial to consider durability, performance, and energy efficiency. Achieving a balance among these factors is essential for the success of your solar project. By implementing the following 11 PCB design tips, you can enhance your solar-powered devices’ manufacturability and overall effectiveness.

11 Essential PCB Design Tips for Solar Panel Electronics

- Involve your PCB vendor early: Engaging your electronics manufacturing vendor in the early stages of PCB design is crucial. Their experience and expertise can help identify potential issues that may need to be apparent on paper. Collaboration with your vendor can prevent costly long-term problems, ensuring smooth device manufacturing, performance, and certification approvals.

- Consider the efficiency of the solar panel: The efficiency of your solar panel plays a significant role in the overall performance of your electronics. Different types of solar panels, such as monocrystalline, thin film, or polycrystalline, offer varying levels of efficiency. It is essential to confirm the efficiency of the panel you intend to use before proceeding with the PCB design.

- Confirm battery and panel sizes: A battery backup system is essential for solar-powered devices that require continuous operation. When designing your solar PCB, consider the duration the system should function when the solar panel’s power is reduced to 0%. Factors like environmental conditions can impact the panel’s performance, so choosing a battery with adequate capacity ensures uninterrupted device operation.

- Assess the need for power-intensive modules: Certain applications, such as thermal printers, Wi-Fi, and GSM modules, require higher power consumption. Accurately assessing the power requirements of these modules is crucial for designing a solar panel system that can seamlessly power such components.

- Consider firmware architecture: Designing an efficient firmware structure is essential for optimizing energy savings in solar-powered embedded systems. Incorporate features that enable the microcontroller to enter “deep sleep” mode when not in use, prolonging the device’s operational time during unfavorable conditions. Implementing a separate power channel for logistics and peripheral integrated circuits reduces unnecessary power consumption during idle periods.

- Build a corrosion-resistant box: Given that solar devices are exposed to the elements, ensuring that the circuit boards inside a solar device are protected from harsh conditions is essential. They provide a corrosion-resistant box with temperature control safeguards against hailstorms, extreme temperature changes, and hurricanes, which can compromise the system’s performance and longevity.

- Achieve easy current flow: Optimizing current flow within the solar panel circuit board is crucial for maximizing energy efficiency. Use online calculators to determine the optimal line width that facilitates easy current flow. Additionally, when designing the PCB layout, alternate the wiring directions between consecutive layers to enhance current flow and minimize resistance.

- Get your PCB component sizes right: Choosing appropriately sized components during the design stage prevents complications during manufacturing. If space allows, opt for slightly larger components that improve manufacturability. Investing in the right component sizes early on can streamline production and reduce flaws.

- Go lean: Lean PCB design reduces engineering, testing, processing, handling, and stock management requirements. Fewer parts lead to cost and assembly time reductions. Complex designs featuring surface mount technology (SMT) on both sides or through-hole components on both sides tend to be costlier. Minimize unnecessary complexity unless it is critical to the product’s functionality.

- Choose a suitable surface finish: Selecting the right surface finish is crucial for PCB design. The surface finish should protect the circuitry from corrosion while providing a solderable component surface. Avoid using a RoHS-compliant hot air solder leveling (HASL) finish, as it tends to remove solder from the PCB. Electroless nickel immersion gold (ENIG) is a cost-effective and practical option that offers a flat surface and easy solderability.

- Space your PCB component layout appropriately: Proper component placement in the PCB design significantly impacts efficiency and durability. Components placed too close to the edge may be prone to cracking or functional issues. Ensure there is sufficient routing space around components near the edge and throughout the entire PCB layout to facilitate proper wiring and prevent errors that could affect the system’s efficiency.

Conclusion:

Following the 11 PCB design tips above for solar panel electronics, you can improve your solar-powered devices’ manufacturability, performance, and durability. Collaborating with your PCB vendor, considering panel efficiency, confirming battery and panel sizes, and optimizing current flow are essential steps in designing effective solar PCBs. Implementing these tips will help you create robust solar-powered systems capable of withstanding outdoor conditions while maximizing energy efficiency.